à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ ठसर निरà¥à¤à¥à¤·à¤£ पà¥à¤°à¤£à¤¾à¤²à¥

à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ ठसर निरà¥à¤à¥à¤·à¤£ पà¥à¤°à¤£à¤¾à¤²à¥ Specification

- रंग

- silver

- प्रॉडक्ट टाइप

- औद्योगिक असर निरीक्षण प्रणाली

- पावर

- इलेक्ट्रोनिक वोल्ट (v)

- उपयोग

- औद्योगिक बियरिंग निरीक्षण

- सटीकता

- 99 %

- ऑपरेटिंग मोड

- स्वचालित

à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ ठसर निरà¥à¤à¥à¤·à¤£ पà¥à¤°à¤£à¤¾à¤²à¥ Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- कैश इन एडवांस (CID)

- आपूर्ति की क्षमता

- 10 प्रति दिन

- डिलीवरी का समय

- 5-7 महीने

- मुख्य घरेलू बाज़ार

- ऑल इंडिया

About à¤à¤¦à¥à¤¯à¥à¤à¤¿à¤ ठसर निरà¥à¤à¥à¤·à¤£ पà¥à¤°à¤£à¤¾à¤²à¥

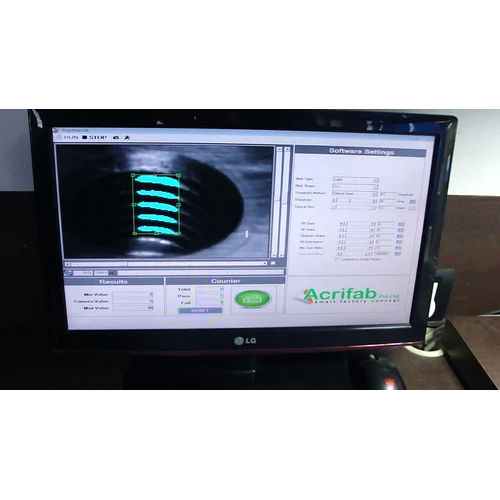

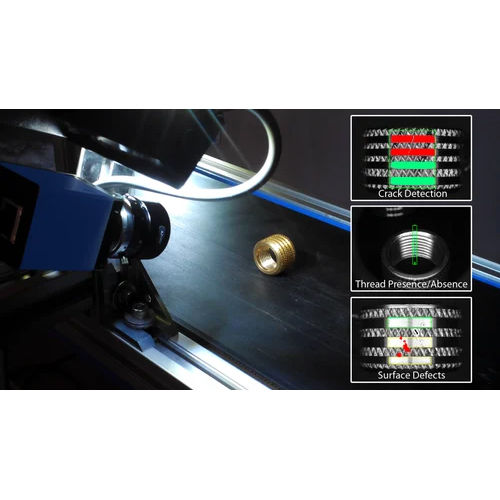

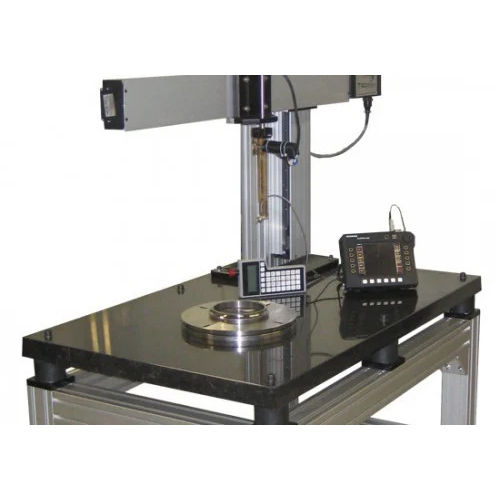

The Industrial Bearing Inspection System is a state-of-the-art solution designed for precision and reliability in inspecting industrial bearings. With an immaculate silver finish, this advanced system leverages an automatic operating mode to streamline inspection processes. Delivering an exceptional accuracy rate of 99%, it ensures superior performance for critical applications. Powered by electronic volts, the system is energy-efficient and built to withstand industrial demands. Ideal for manufacturers, suppliers, distributors, and exporters, this inspection system is engineered to enhance productivity and quality control in industrial environments. Its cutting-edge design ensures seamless integration into inspection workflows, offering a reliable solution for detecting bearing defects and validating performance standards quickly and efficiently.

FAQs of Industrial Bearing Inspection System:

Q: What color is the Industrial Bearing Inspection System?

A: The system features a sleek silver finish.Q: What is the operating mode of this inspection system?

A: The Industrial Bearing Inspection System operates automatically for ease of use and improved efficiency.Q: How accurate is the Industrial Bearing Inspection System?

A: The system boasts an impressive accuracy rate of 99%, ensuring precise inspection results.Q: What type of power does the system require?

A: The system is powered by electronic volts (v), offering reliable and consistent performance.Q: Who is the intended user of this inspection system?

A: The system is designed for industrial use, specifically for inspecting bearings in manufacturing, trading, and supply operations.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in ऑटोमोटिव पार्ट निरीक्षण प्रणाली Category

गुम ऑपरेशन डिटेक्शन सिस्टम

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

सटीकता : 99 %

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

कंट्रोल मोड : प्रदर्शन संचालन

ऑटो पार्ट सरफेस इंस्पेक्शन सिस्टम

मूल्य या मूल्य सीमा : आईएनआर

माप की इकाई : यूनिट/यूनिट

सटीकता : 99 %

न्यूनतम आदेश मात्रा : 1

मूल्य की इकाई : यूनिट/यूनिट

कंट्रोल मोड : प्रदर्शन संचालन